Overview

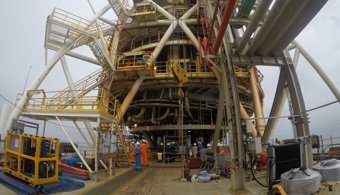

James Fisher was contracted by ScottishPower Renewables (SPR) to deliver an integrated marine services package, including UXO, during the construction of the East Anglia ONE (EA1) offshore windfarm, approximately 40 km off the coast of Suffolk. EA1 comprises 102 turbines generating 714MW.

Challenge

The James Fisher team was engaged to carry out a thorough UXO disposal campaign at the EA1 windfarm site. This area of seabed contains the densest concentration of subsea munitions in the UKCS, many the remnants of WWII where an estimated 10 to 20 percent of bombs and mines remain unexploded. This potential risk of unexploded ordnance (UXO) posed a significant challenge to the offshore windfarm construction.

Solution

During the initial UXO disposal campaign 796 potential UXO targets were identified at EA1. 69 items were confirmed as ‘live’ UXOs and were safely disposed of using the Barracuda UXO disposal system, enabling the construction to proceed without delays. To comply with marine licensing the team deployed a bubble curtain for shallow water targets, as the first project in the UK to use this technology. The bubble curtain system uses air bubbles released from a perforated hose on the seabed to create a sound barrier that can protect marine life during detonation. Additional support services were provided including guard vessels, offshore site boundary marker installation and maintenance (to prevent unauthorised entry), Fern Communications WaveCom™ for reliable communication, and marine coordination through OWMS® for real-time tracking and data, to improve site safety and operational effectiveness.

Value to customer

- Successful UXO disposal to ensure site safety during construction

- First deployment of bubble curtain

- First power generation milestone reached with initial turbines successfully exporting power to the onshore substation, and subsequent commissioning at regular intervals

- Deployment of OWMS® and WaveCom™ to provide significant economic benefits and reduction in offshore personnel and vessels

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2024

Annual Report 2024