Overview

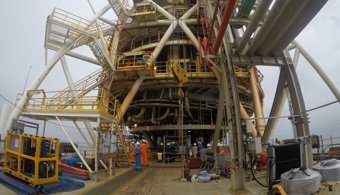

James Fisher, in collaboration with Modec, supplied a custom-built bearing monitoring solution to help restore production for a compromised floating production storage and offloading unit (FPSO) off the coast of Ghana.

The Challenge

Industry partners Modec and Sofec required a bespoke bearing monitoring system for an FPSO operating in the Jubilee oil field after wear issues with the FPSOs bearing had immobilised the vessel and were impacting production targets. An urgent solution was essential to minimise downtime. The challenge required the team to design and install a solution that would allow the FPSO to maintain safe production levels while essential repairs were conducted.

Frank Rose, business development managerJames Fisher, Modec and Sofec have built a strong relationship over a period of almost 20 years working on 14 projects together. This proved invaluable as James Fisher delivered an established solution tailored to the needs of the turret repair team. Our field service and project management team worked closely with the operations team in Ghana to train personnel and install the system. Ultimately, the jacking operation was completed in advance of the original deadline.

Value to customer

- Custom-built bearing monitoring solution helped to restore the FPSO production capabilities and continue operations with minimal downtime

- System delivered precise real-time monitoring data.

- Solution performance enabled delivery ahead of schedule, helping to significantly reduce downtime and associated cost

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2023

Annual Report 2023