Overview

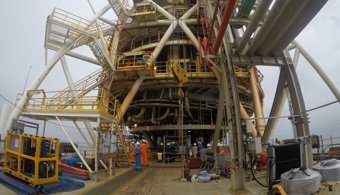

Forth Logistics Marine Services at Port Edgar, Edinburgh required a long-term marine fendering solution and a robust alternative to traditional rubber fenders for two workboats, Wave Dance and Wave Spirit, to enhance vessel durability and reduce maintenance costs

The Challenge

Forth Logistics required a fendering solution what can withstand regular exposure to harsh marine environments and rigorous conditions. With regular fender damage, frequent repairs, with replacements every three months Forth Logistics needed a durable marine fendering solution that would reduce maintenance costs and improve vessel uptime while providing reliable protection for their fleet.

Our Solution

Fendercare Marine, part of James Fisher and Sons plc, delivered an innovative Poly-Marine vessel fendering system. Poly Marine fenders use advanced polymer technology to offer a durable alternative to rubber. Their high abrasion resistance and impact protection makes them an ideal solution for vessels operating in extreme conditions. Key benefits include ultra-strong lightweight material, high resistance to UV and chemicals, low coefficient of friction for smoother vessel operation, longer lifespan compared to conventional rubber fenders and customisable to fit unique vessel requirements, and simple installation process required no special tools.

Sandy McPhail, owner at Forth LogisticsPort Edgar, EdinburghThe installation was simple compared to conventional rubber products; the fendering was significantly more flexible, easier to drill/cut and required no special tooling for installation.

It goes without saying that the biggest benefit we have seen is the dramatic reduction in maintenance and vessel downtime costs, which has far outweighed the increase in capital cost over conventional rubber fendering.

James Fisher's fixed fendering service would be an asset for any fleet and has my highest recommendation based on our experience.

Value to customer

- Reductions in maintenance and vessel downtime costs outweighing the initial capital investment

- Durable fendering solution with reported reduction in operational expenses compared to traditional rubber fendering systems

- Robust design offering a significant reduction repairs and replacements

- Improved overall operational efficiency

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2023

Annual Report 2023