Overview

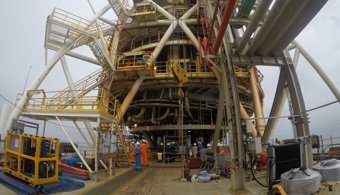

JFD, part of James Fisher and Sons plc was commissioned to perform a submarine hull testing operation at their National Hyperbaric Centre facility in Aberdeen, UK. A comprehensive pressure test was to be carried out on a submarine hull to ensure the equipment can withstand the extreme conditions encountered during subsea missions, supporting safe operations and enhancing submarine safety and reliability.

The Challenge

The size of the submarine hull presented logistical challenges. At around 800 cm in length, for the hull to access the testing facility required the removal of the hyperbaric chamber door to allow the submarine hull to be safely manoeuvred into the testing chamber with only a few centimetres of clearance.

Our Solution

JFD deployed a 100-tonne mobile crane to offload the submarine from its trailer onto a specially designed trolley for transport into the National Hyperbaric Centre. Once in the hyperbaric chamber it was securely strapped down to prevent buoyancy during the underwater testing simulation. The chamber was filled with water and the hull subjected to intense pressure to replicate real-world subsea conditions. The hyperbaric chamber testing provided verification that tge equipment would perform safely and reliably under extreme conditions.

Value to customer

- Rigorous testing demonstrated the hull's ability to withstand pressures expected during deep-sea operations, ensuring submarine safety

- Access to National Hyperbaric Centre world-class facility and equipment

- Experienced marine engineering team

- Safe and controlled environment

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2023

Annual Report 2023